Electronics are getting smaller, smarter and ever-more ubiquitous, and the minute parts that make them work need to be constantly re-engineered to keep pace with rapid change.

University of Queensland researchers aim to be at the forefront of improving the next generation of smartphones, computers and electric cars, with the launch of a new project at UQ’s Nihon Superior Centre for the Manufacture of Electronic Materials.

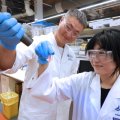

The researchers, led by Associate Professor Kazuhiro Nogita and Dr Stuart McDonald from the School of Mechanical and Mining Engineering, will work with two research staff and six PhD students to develop a range of solder alloys suitable for harsh operating conditions such as those found in the engines of hybrid and electronic cars.

“Solder alloys are the key to connecting all the different electronic parts together, and are critical to improving lifespans on devices like your smartphone,” Dr McDonald said.

Soldering is a process in which two or more items (like wires or circuitry) are joined by melted and solidified metal.

“This entirely industry-funded project will focus on developing scientifically researched commercial products,” he said.

Associate Professor Nogita said small devices such as mobile phones contained thousands of soldered joints.

He said earlier lead-based solders were no longer used in consumer devices, and new alloys had to be developed to replace them.

“Consumers also expect longer lives and better quality from their devices, so the internals need to keep up.”

The project is supported by $460,000 in funding from Nihon Superior.

Media: Associate Professor Kazuhiro Nogita, k.nogita@uq.edu.au, +61 7 3365 3919; UQ Communications Casey Fung, c.fung@uq.edu.au, +61 7 3365 8525.

.jpg)