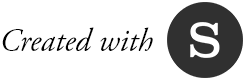

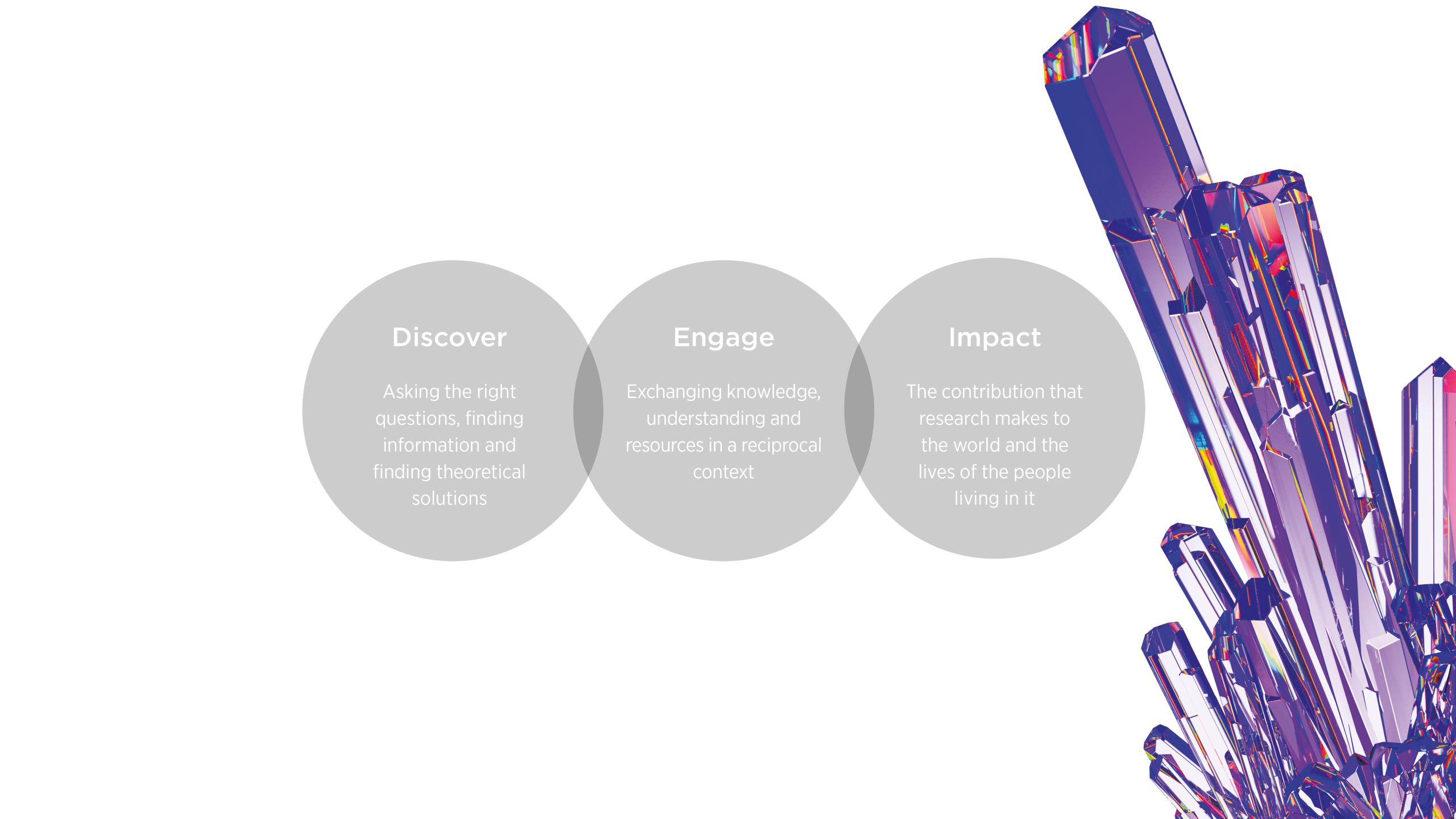

Tasting success

with probiotics

UQ research is enabling ‘good-for-gut’ bacteria to be cheaply and easily added to lactose-free food and drinks, allowing more people to experience the benefits of probiotics.

When Professor Bhesh Bhandari and his team at UQ's School of Agriculture and Food Sciences began researching encapsulation methods for active ingredients such as probiotics, they had a major challenge to overcome: how to ensure these 'good-for-gut' bacteria could safely make their way to a person's gut.

Probiotics were known to provide many health benefits, but could not survive the trip to the intestine due to the highly acidic environment of the stomach.

"This means they’d have to be transported via needle or suppository – which are much more expensive and inconvenient methods than simple swallowing,” Professor Bhandari says.

“We needed to find some good packaging that tasted okay, was non-toxic, and was relatively cheap to produce commercially.”

Enter PERKii® – the world’s first non-fermented, low-calorie probiotic water that incorporates UQ’s novel ProGel™ technology to deliver beneficial bacteria safely to the gut.

Sold in more than 2000 stores across Australia and New Zealand, PERKii provides a pleasant-tasting alternative to traditional dairy-based probiotic products, and is just one application of UQ’s world-first ProGel encapsulation method that has the potential to revolutionise gut health on a global scale.

Getting the packaging right

Beverage, pharmaceutical and dairy companies have long been creating products that can enhance people’s quality of life.

Examples include probiotics, therapeutic biologics and drugs, nutraceutical fish oils and lactose-free fortified foods.

The problem with these products is that many are unstable during processing and storage, and when in the highly acidic gastric environment.

“The targeted delivery point of such compounds is the intestine, where their absorption takes place,” Professor Bhandari says.

“This means that if they are to be effective, they need some protection as they pass through the stomach.”

Early UQ research into methods to protect food bioactives and pharmaceuticals in alginate gels were not feasible on a large scale because of the many small stop-start processing points involved and their inability to produce small gel particles.

Then Professor Bhandari and his team discovered a way to use micron-size gel particles to effectively ‘trap’ the active compounds until after they pass through the stomach’s acidic environment – an invention they named ProGel.

“Our discovery has completely changed the game of encapsulating different classes of actives,” Professor Bhandari says.

“The microgels ensure the bacteria survive long enough to make it to the intestine where they do their work, and are particularly suited to the protection of actives in aqueous environments like drinks.”

Professor Bhandari says ProGel also offers manufacturers significant cost savings.

“ProGel’s continuous and scalable process has opened up opportunities for our technology to be used in a range of manufacturing applications – especially as we use safe, non-chemical and non-toxic food ingredients such as alginate,” he says.

“Producing calcium alginate microgels in large-scale commercial volumes keeps ingredient costs down.

“No heating, electrical components or moving parts are involved, and the continuous manufacturing process itself requires minimal labour.”

Image credit: Getty Images/Isabel Pavia

The journey to PERKii

Recognising ProGel's enormous potential, UQ's commercialisation company UniQuest patented the technology in 2009 and licensed it to a UQ startup of the same name to accelerate its translation into a consumer product. In 2010, co-investors Uniseed and Brisbane Angels provided $400,000 to test the technology and publicise it widely.

ProGel’s ability to slow and sustain the release of nutrients, protect ‘actives’ from oxidation, mask taste, and maintain stability in wet and dry foods and supplements gave the encapsulation technology a huge advantage in the market – a $50 billion market that had not seen much change in 30 years.

“With ProGel, we could consider the possibility of creating lactose-free foods, as our technology allows calcium to be encapsulated and added to milk and juice,” Professor Bhandari says.

“We also found we could encapsulate the iron-binding functional protein of milk called lactoferrin, which is enormously useful for creating baby food and supplements for elderly people that have anti-microbial, anti-inflammatory and immune-enhancing properties.”

PERKii packaging

A $250,000 grant from Commercialisation Australia allowed the technology to be refined and tested. Then in 2016, with support from UniQuest, Uniseed and Brisbane Angels, ProGel Pty Ltd established PERKii Pty Ltd and raised $4 million in series A funding to develop PERKii – the world's first low-calorie, non-carbonated, fruit-flavoured probiotic water.

Unlike other probiotic drinks, PERKii is neither fermented nor cultured.

“Significantly, PERKii offers lactose-intolerant consumers an easy way to digest and benefit from probiotic supplements, thus serving an unmet need in the health-food industry,” Professor Bhandari says.

“It also contains a probiotic strain, L.casei 431, that can reduce the duration and symptoms of the common cold and flu.”

PERKii packaging

PERKii packaging

Improving gut health in Australia – and beyond

Manufactured in regional New South Wales – and so bringing economic benefits to the town of Mudgee – PERKii was first introduced to the Australian market in 2016.

PERKii's Chief Executive Officer Matt Kowal notes that leveraging the ProGel technology means PERKii has a specific point of difference – both for the retailer and the consumer.

"People are genuinely interested to know the heritage of technology, and how it can benefit them while the retailer appreciates the quality and integrity of the product function," Mr Kowal says.

"With a national launch in Coles scheduled for April 2019, it's a demonstration of how shoppers are demanding more from their food and beverages, which is where PERKii can step in."

Thanks to a $1.53 million investment from the Queensland Government’s Business Development Fund and a distribution deal with Manassen Foods Australia, PERKii drinks are now available in more than 2000 supermarkets, cafes and health food eateries across Australia and New Zealand, including Woolworths, IGA, FoodWorks, THR1VE, AboutLife and Go Vita.

And, ProGel’s potency could soon benefit many more people around the world, with plans underway to take PERKii to the US, Japan, Hong Kong, China, and beyond.

“We are very proud of our ProGel technology,” Professor Bhandari says.

“Not only does it provide better packaging to allow cheap and reliable travel through hazardous stomach acids, the final product tastes good and makes your body feel good too.”

Image credit: Getty Images/webphotographeer

The story so far:

1993: Professor Bhesh Bhandari joins UQ after completing his PhD in food process engineering at Ecole Nationale Supérieure des Industries Agricoles, France, and begins research on spray drying and encapsulation technologies.

1998: Professor Bhandari receives a Small Grant from the Australian Research Council (ARC) to study the Stability of microencapsulated lemon oil-based volatiles in β-cyclodextrin during high temperature short time (HTST) extrusion .

1999: Professor Bhandari also receives an ARC Large Grant to study the implication of glass transition temperature for the spray drying of sugar-rich foods.

2004: Working with Professor Bhandari, Dr Wunwisa Krasaekoopt investigates the encapsulation of probiotics by traditional alginate gelation technology as part of her doctorate studies at UQ, which prompts the development of the Progel technology.

2005: Professor Bhandari receives Department of Defence grant to investigate the Microencapsulation of goat attractants and repellants.

2007: Professor Bhandari receives an ARC Linkage grant to study The molecular mechanism of protein instability in dairy powder systems.

2009: Progel Pty Ltd is founded with seed investment of $400,000 from Uniseed and Brisbane Angels.

2012: Commercialisation Australia provides a $250,000 grant for further technology refinement and product testing.

2014: UniQuest funds research for investigation of Progel encapsulation of lactoferrin, working with both Professor Bhandari and Dr Huma Bukhim.

2015: Professor Bhandari explains the Progel technology in a keynote speech at the International Conference on Food Engineering.

2016: UniQuest forms startup company PERKii Pty Ltd and raises $4 million in series A funding to take PERKii to the Australian market.

2017: PERKii Pty Ltd receives a $1.53 million investment from the Queensland Government’s Business Development Fund to increase PERKii production and expand sales.

2018: PERKii drinks are available in more than 2000 stores across Australia and New Zealand, including Woolworths, IGA and FoodWorks .

2019: PERKii scheduled to launch in Coles supermarkets in April. Planning begins for PERKii to be sold internationally .

Image credit: Getty Images/metamorworks

Opening image credit: Getty Images/Mizina

Contact details

Professor Bhesh Bhandari

Professor Bhesh Bhandari, School of Agriculture and Food Sciences, Faculty of Science

Email: b.bhandari@uq.edu.au

Phone: +61 7 3346 9192

Web: agriculture.uq.edu.au/profile/203/bhesh-bhandari

or researchers.uq.edu.au/researcher/370

This article was last updated on 6 March 2019.

Read more about how UQ researchers are making an impact.

Professor Bhesh Bhandari

Professor Bhesh Bhandari